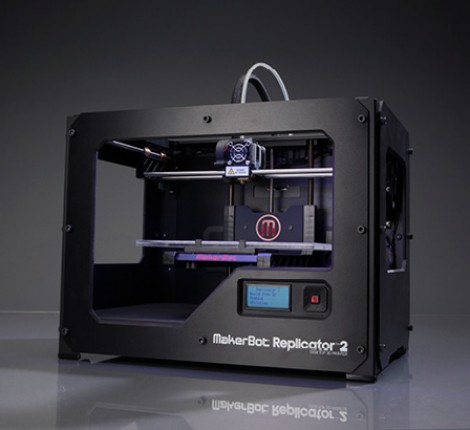

For those of you who don't know what a 3D printer is, it is a machine that can make parts out of plastic from a CAD model. It takes a 3D computer CAD model, and slices it up into thin layers. Then the printer heats up plastic and lays it down layer by layer until it has made a real part that matches what the model shows. At my work we have a very large and VERY expensive 3D printer that we use for mockups, test fitting parts and even some temporary tooling. But over the last few years, much smaller and more affordable options have started showing up on the market. One of the really fancy looking ones out there right now is the MakerBot Replicator 2.

- Build Size: The maximum size of a part that can be built/printed. This varies greatly from printer to printer, the smallest one I saw was 4" x 4" x 4" and the largest home/desktop printer build size I saw was around 12" x 8" x 8".

- Print Material: Some of the printers can only print in ABS plastic, some can only use PLA (polylactic acid). I wanted a printer that could print in both.

- Heated Bed: The plate that the printer prints onto needs to be heated in order for some plastics to stick to it properly so if he is going to print with all different materials I wanted a heated bed

- Cost: I couldn't spend too much so I had to evaluate what features I could get for my budget.

After a lot of research, I found the Airwolf 3D printer (a derivative of the Reprap 3d printer). It has an 8" x 8" x 8" build platform, prints in both ABS & PLA, has a heated bed, and had an option to buy a kit to put it together yourself which put the cost close to what I was looking to pay.

www.thingiverse.com

It's a free site where people upload their CAD models and share them so everyone can find more designs to print out. There's everything from fishing lures, to jewelry, to puzzle boxes, to vases and beyond. It's pretty awesome!